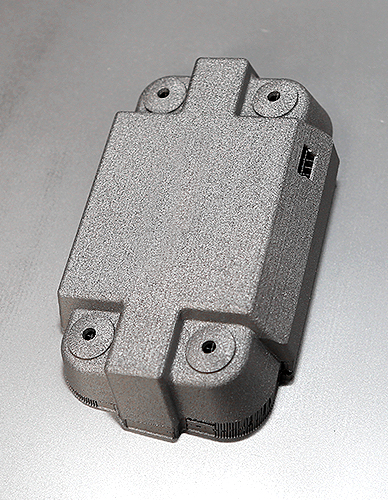

ENAVISION 400 METAL ADDITIVE MANUFACTURING MACHINE

Ready to Do Big Jobs...

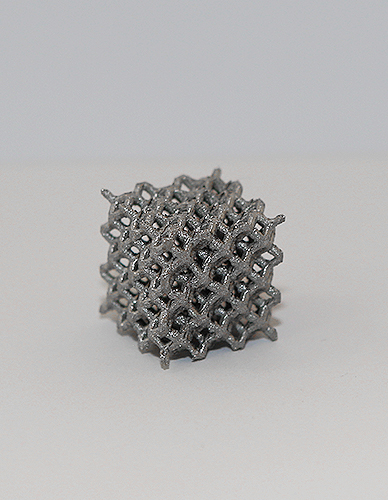

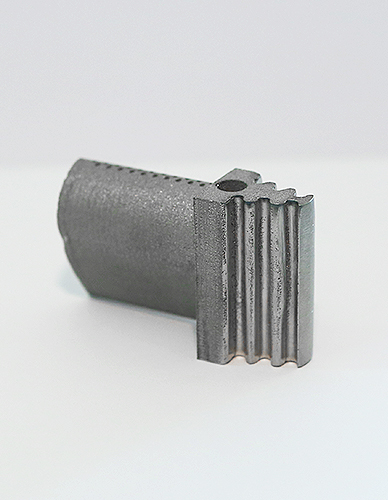

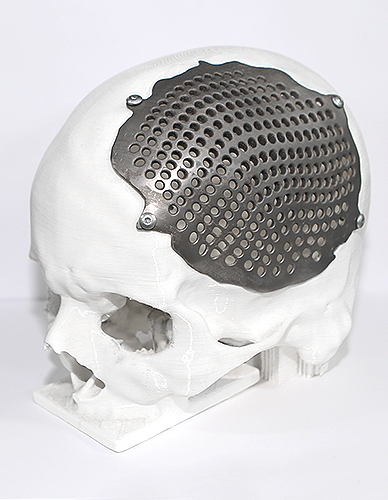

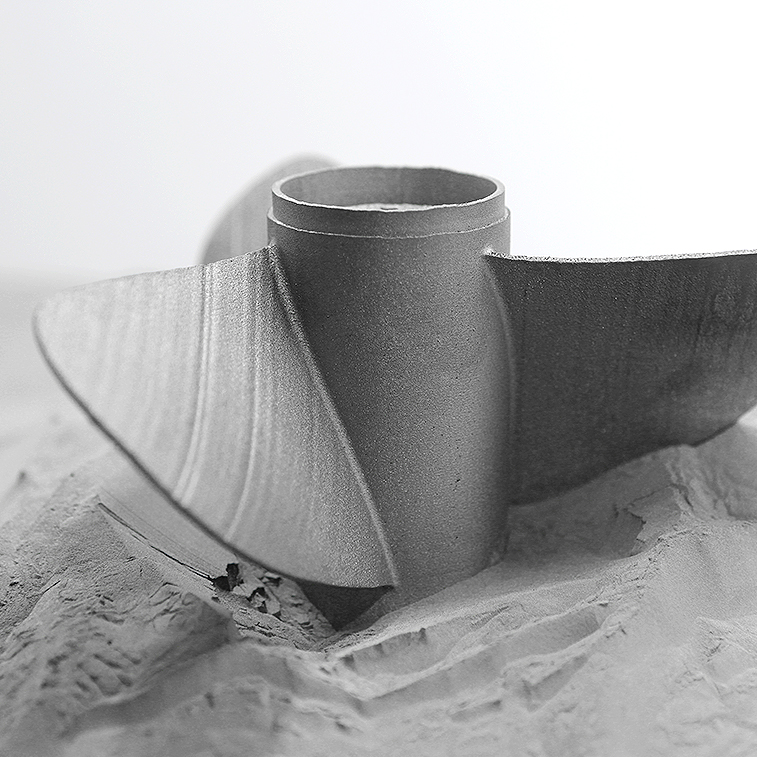

ENAVISION 400 has the ability to produce large parts using different metal alloy powders with a production volume of 400x400x300 mm . With its advanced speed and optional dual or quad laser systems, it provides increase in production and productivity.

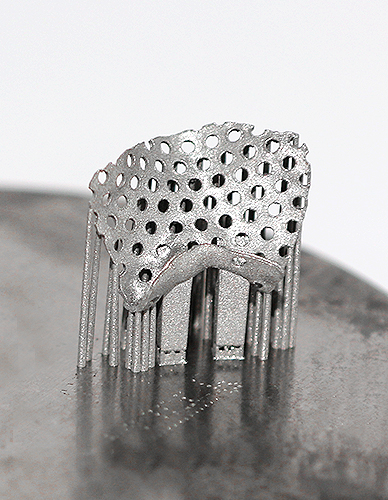

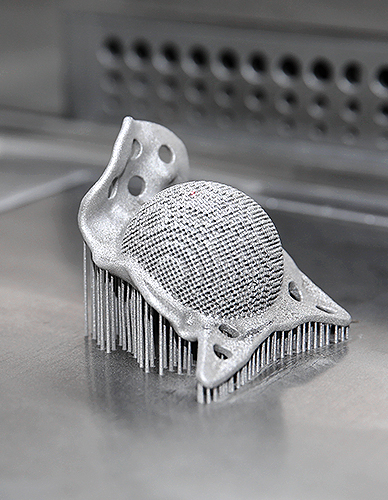

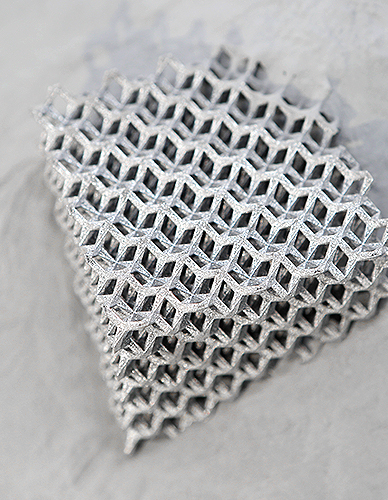

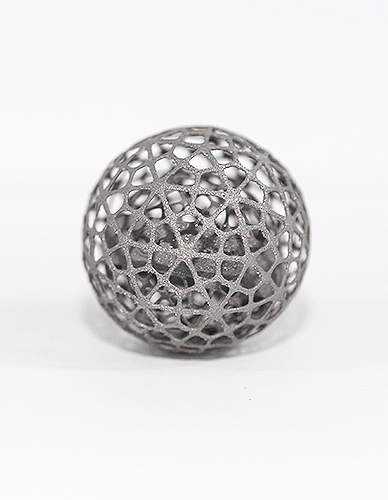

ENAVISION 400, like all ENAVISION series, works with a powder bed fusion (DMLS / SLM) Selective Laser Melting method. Produced Parts by this method can be produced with a density of over 99% in standard parts and with good mechanical properties.

ENAVISION 400 has the capability to meet different customer needs with its single, dual and quad laser versions. It offers unlimited freedom and flexibility to its users with its open parameter structure.

With Magics Print for ENAVISION, customized for ENAVISION 400 by Materialize, you can maximize your productivity in the additive manufacturing world. Besides the ER 4.0 software developed by Ermaksan engineers within the scope of Industry 4.0 ensures continuity and efficiency in production. Step into the smart production approach by optimizing your manufacturing processes with minimum cost and maximum efficiency.