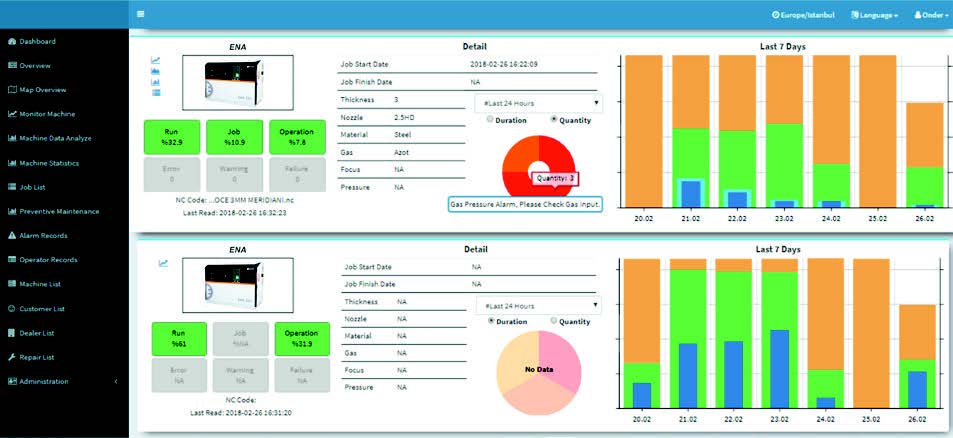

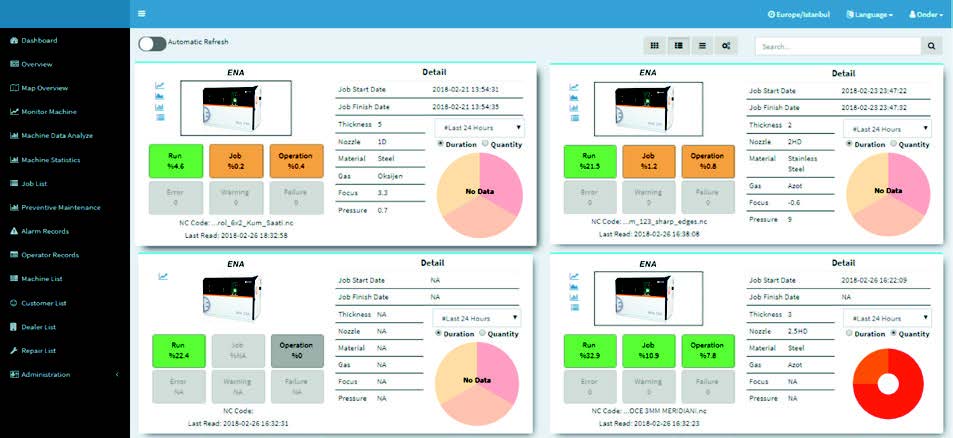

Enables the tracking of the error, alarm, efficiency, etc. data of all machines operating in the field on a single screen. So we contribute in the realization of production targets by our customers.

Enables you to track of the type of the material in the machine, thickness, used nozzle, used gas, pressure, etc. technical data. So you can display the technical data of your machine remotely and prevent the possible errors.

Enables the tracking of the performance of the machines, quality and availability data rates in a graphic form. So sustainability and efficiency is provided in the production.