PART PREPARATION SOFTWARE WORK FILE FORMATION

Magics

- Besides time assumptions, volume and cost assumptions can be made, too.

- Production order can be sent to more than one printer at the same time.

- On a single production table, more than one different/same part can be scanned at the same time and different production parameters can be applied to each of them.

- There are more formats to be realized by loading part manually.

- Different sensitivities may be required in different regions on the part surfaces.

- One surface can be divided into different surfaces and different mesh structures can be obtained.

- Porous indoor structures can be formed with different geometry and adjustable parameters and so the part lightens and the rigidity is protected at a certain rate.

- The surface can be divided into different surfaces and different supporting surfaces can be formed and different supporting structures can be applied to these.

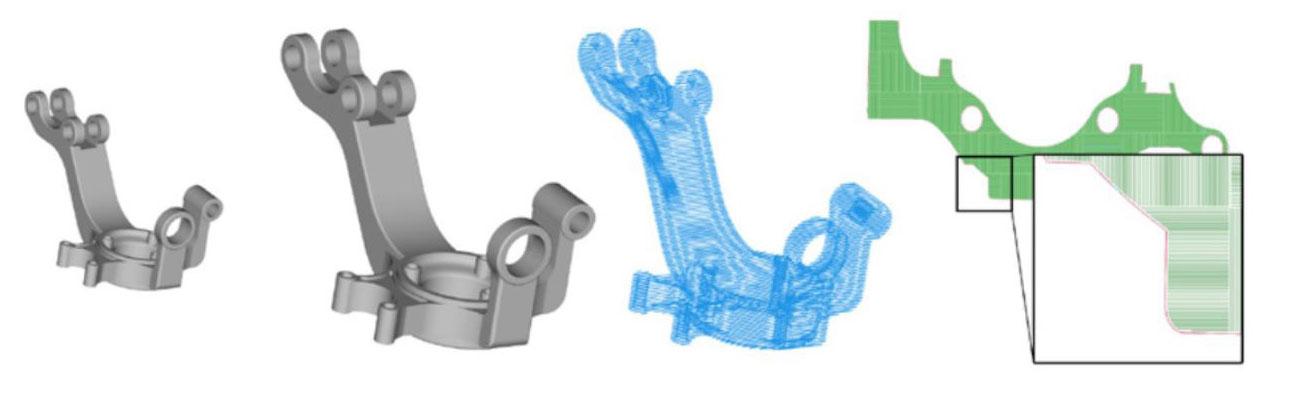

Part Drawing

Scaling

Slicing

Scanning and Ordering

Import

- By using “Magics”, you can import various file formats together with the colour and format information and control your original data without losing them.

- You can import the following file formats with “Magics” RP:

- VRML (*.wrl, *.vrml, *.x3dv),

- Rhino (*.3dm),

- Sketchup (*.skp),

- OBJ (*.obj),

- 3DS (*.3ds, *.prj),

- PLY (*.ply, *.zcp),

- Z- PR (*.zpr),

- FBX (*.fbx),

- COLLADA (*.dae),

- X3D (.x3d),

- 3MF (*.3mf),

- DXF (*.dxf),

- STL (*.stl)

Repair

- Frequently encountered problems can be resolved with a simple press of the ‘Autofix’ button.

- The ‘Repair Wizard’ guides you through solving com- plex issues, step by step.

- Model architectures can be repaired, and thickness can be added using the ‘ShrinkWrap’ function. (All problems can be addressed by enveloping the original model with a thin layer and compressing it.)