ENAVISION 120 METAL ADDITIVE MANUFACTURING MACHINE

Discover The New ENAVISION 120 Metal 3D Printer

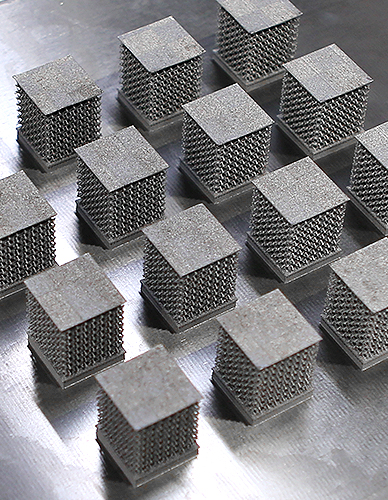

Investing in the ENAVISION 120 additive manufacturing machine provides a fast, reliable, and cost-effective solution. With its compact design and a production volume of Ø120 mm x 80 mm, ENAVISION 120 seamlessly blends practical functionality with ergonomic design. Tailored for laboratories and office environments, the new design is the perfect solution for applications in dental, medical, universities, and research institutes.

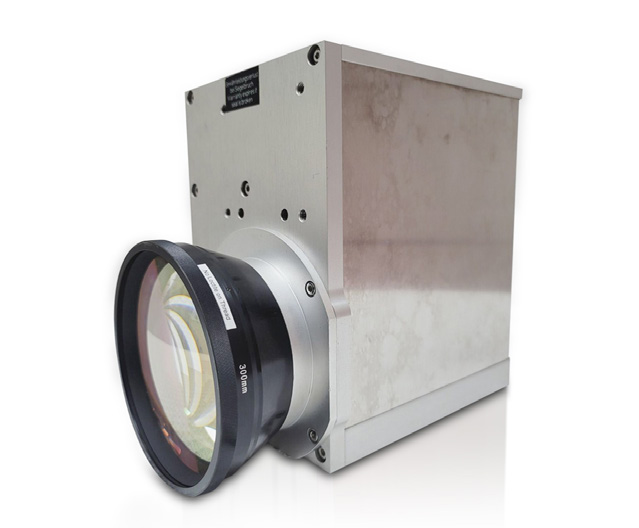

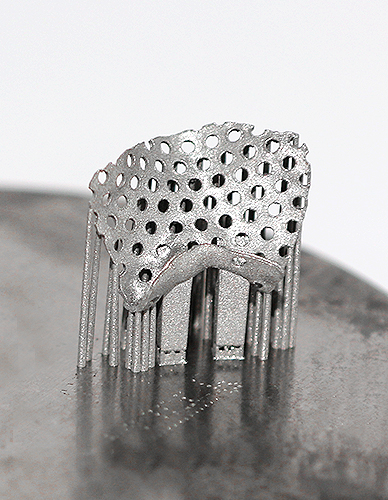

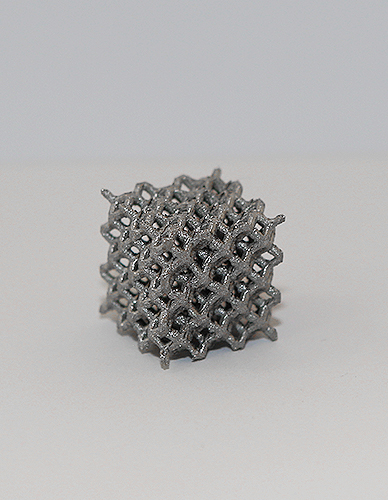

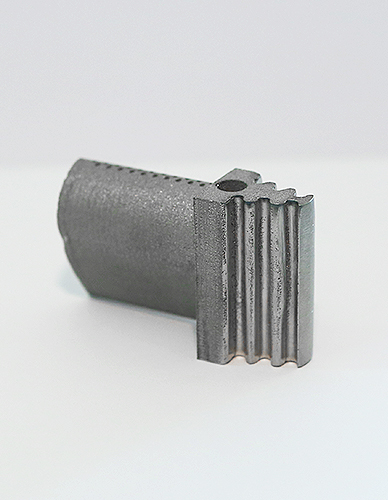

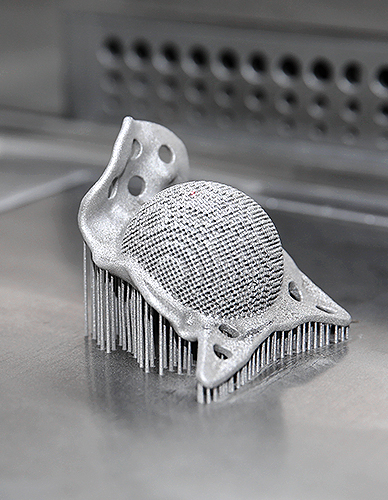

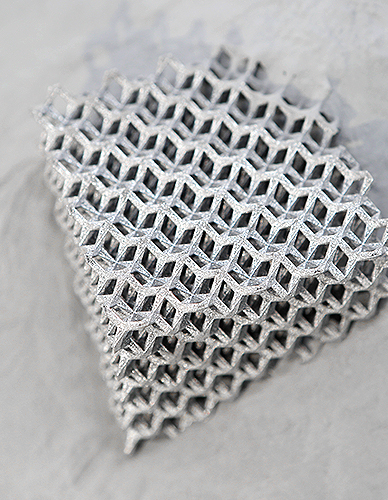

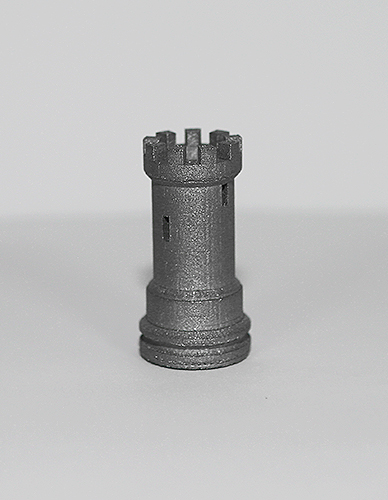

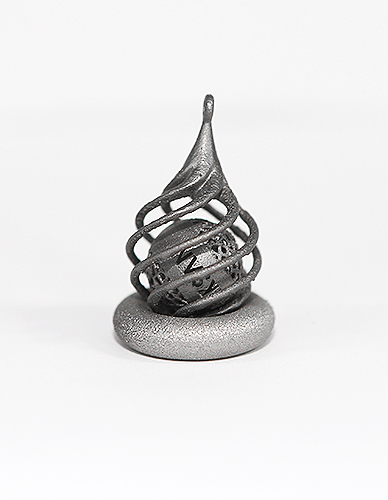

The 3D printer utilizes the Laser Powder Bed Fusion (L-PBF) method. By processing metal powders using this technology, the result is parts with a density of over 99% and excellent mechanical properties, meeting industry standards. Users have the freedom to optimize machine parameters based on part geometry and specific production needs, allowing for complete control over the process. This flexibility ensures seamless adaptation to various material types, ensuring both versatility and performance in every use case.

Furthermore, the machine's advanced features ensure consistent and reliable results. Its precise layer-by-layer deposition technology guarantees the production of complex geometries and intricate details with minimal wastage of materials. This not only reduces production costs but also contributes to a more sustainable manufacturing process.