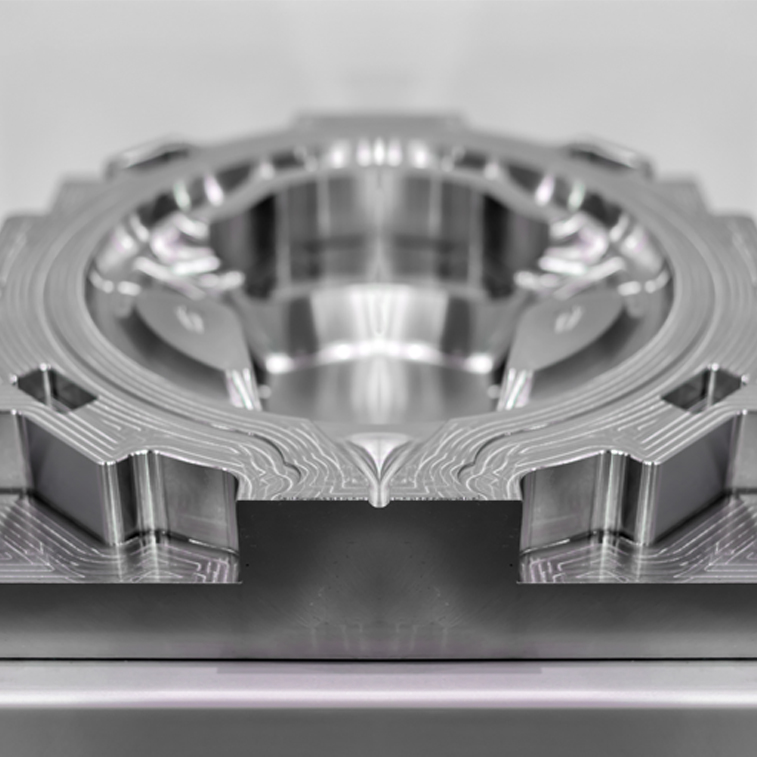

Fast and Flexible Solutions for Mold Manufacturing

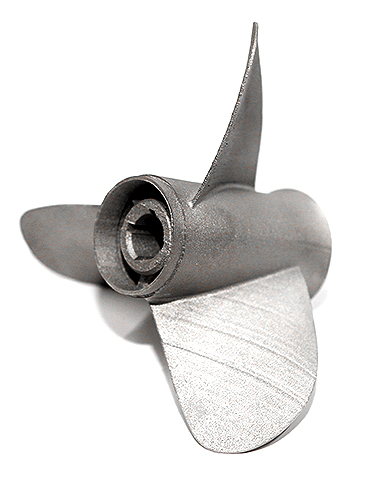

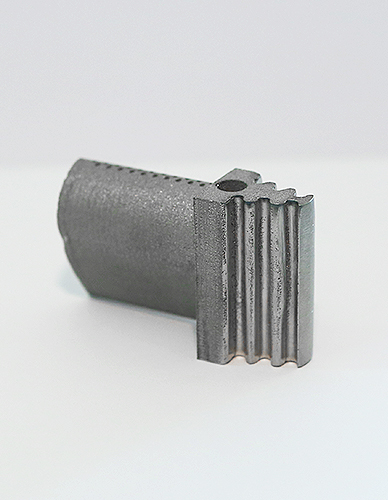

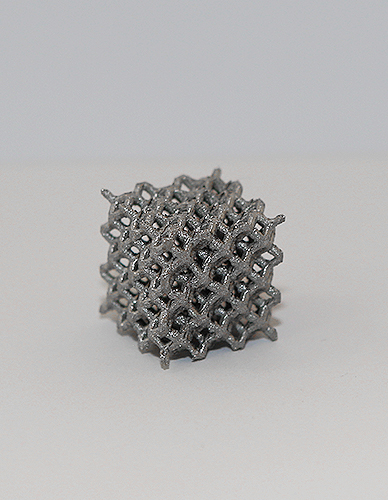

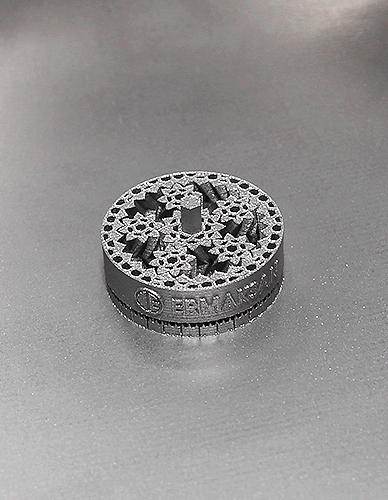

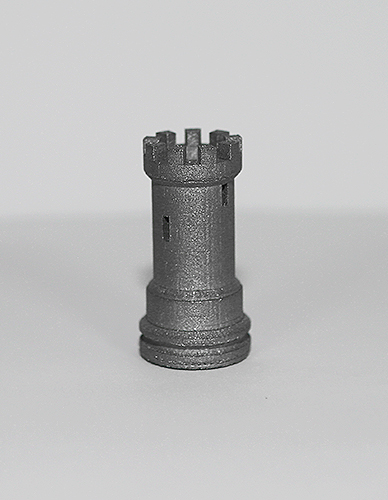

Part manufacturing with additive manufacturing offers a wide range of solutions for industries. Metal parts can be produced without the need for traditional processing methods and without limitation in geometry. The first use of metal additive manufacturing was in high-end technology industries such as space and aerospace applications. With the development of technology over time, its use in the medical, automotive and molding sectors has become widespread and effective.

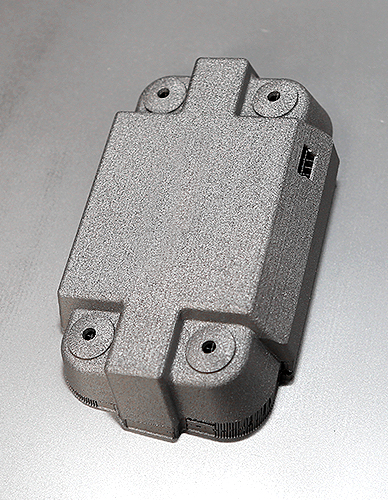

It is possible to manufacture the equipment and molds required for traditional production, with additive manufacturing technologies, quickly and with more advanced features.

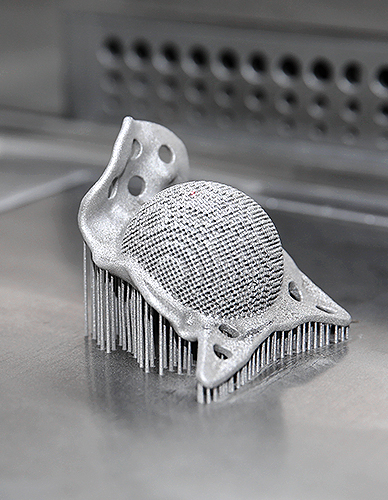

Direct integration of molds, mold inserts and cooling channels produced with ENAVISION Additive Manufacturing Technologies can be achieved. Optimized heat dissipation ensures shorter cycle times, increased efficiency and plastic product quality in injection molding processes. It reduces thermal stresses in the mold and extends its service life.