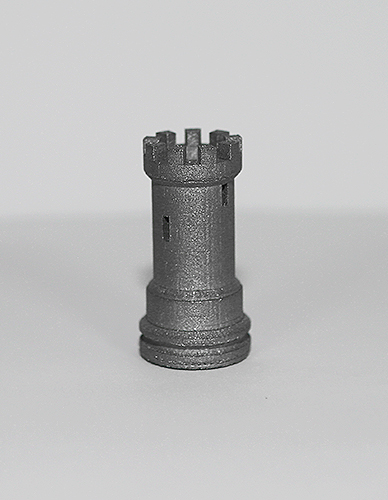

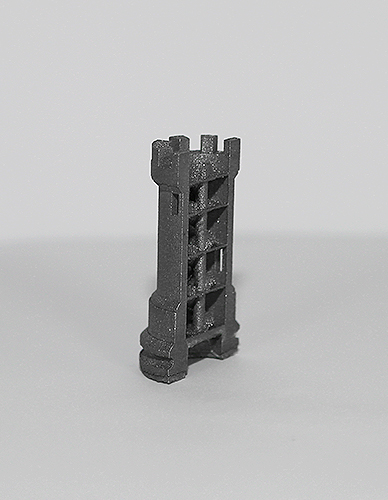

ENAVISION 165 METAL ADDITIVE MANUFACTURING MACHINE

Cost-Effective Solution for High Productivity

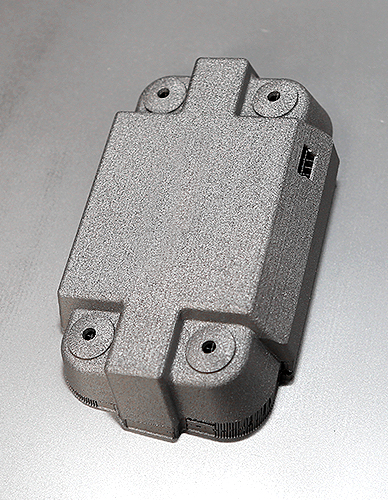

ENAVISION 165 with a production volume of Ø165 x 100 is presented to its users with a round production platform. It is designed for both industrial and laboratory environments with its compact and ergonomic structure.

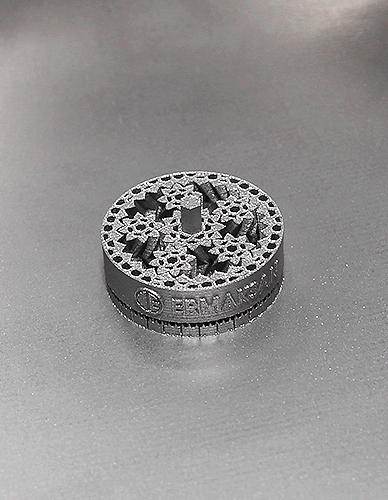

ENAVISION 165 developed to provide maximum productivity with lower investment costs, especially in the dental and medical sectors. It allows for customized applications in the dental and medical industries, also ideal for use in office production environments such as universities and research institutes.

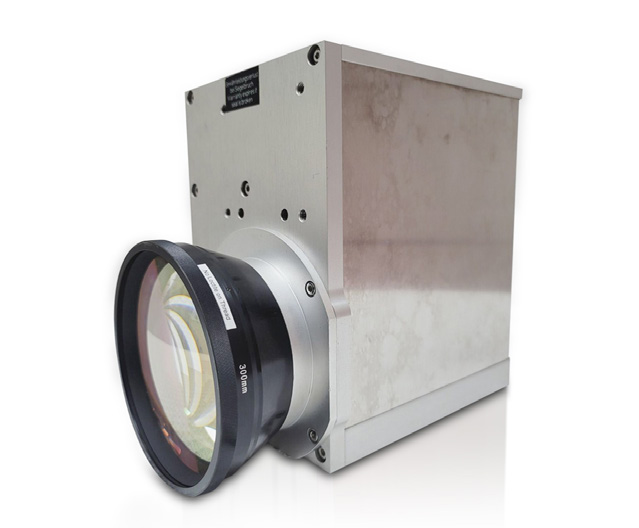

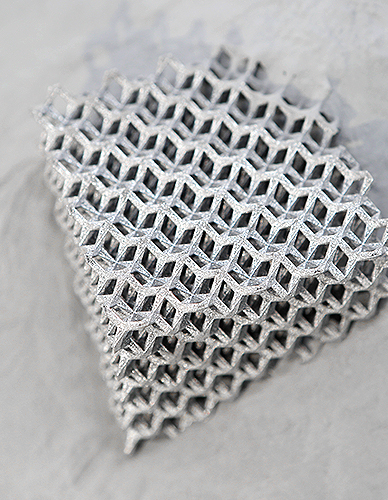

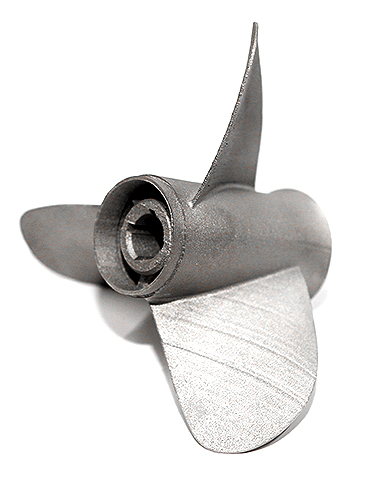

Offering flexibility and unlimited freedom to users with its open parameter structure, this model is equipped with a single and dual laser versions to meet different customer demands. It gives its users the freedom to optimize machine parameters according to part geometry and production requirements. Users can control all process parameters for each material type.

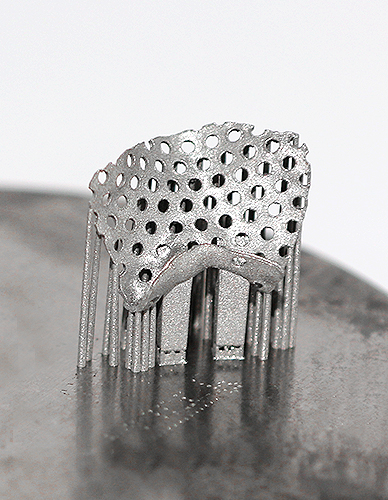

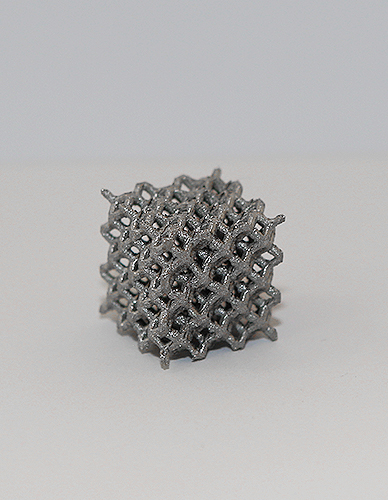

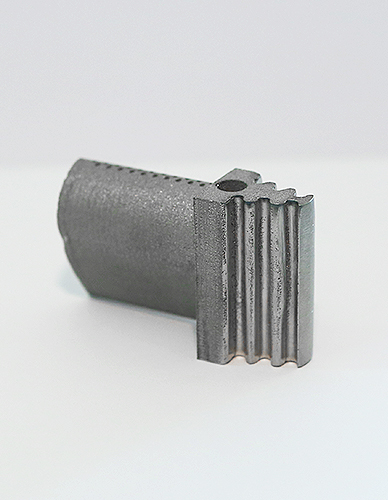

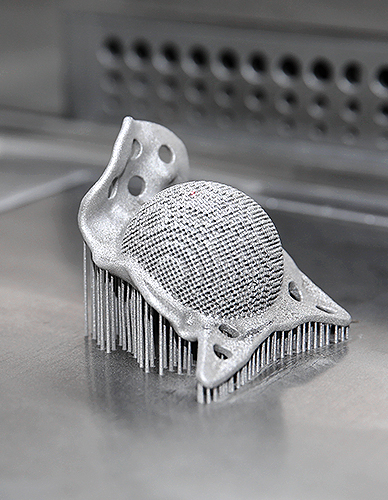

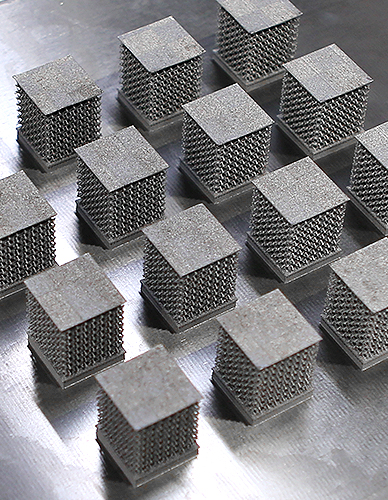

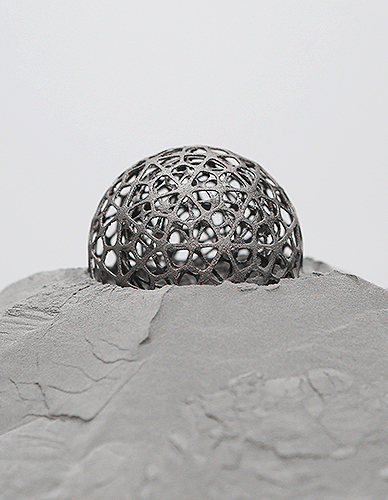

In this technology, which uses the powder-bed selective laser melting method, it starts by laying the metal powder at the desired layer height on the production platform and completely melts the metal powder in the required areas in the part model to be produced by a high power laser. Operations in one layer are performed repeatedly in each layer until production is complete. Parts manufactured by laser melting can be produced with a density of over 99% and good mechanical properties in standard parts.