ENAVISION 250 METAL ADDITIVE MANUFACTURING MACHINE

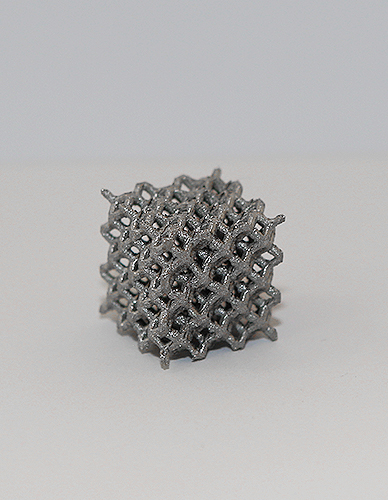

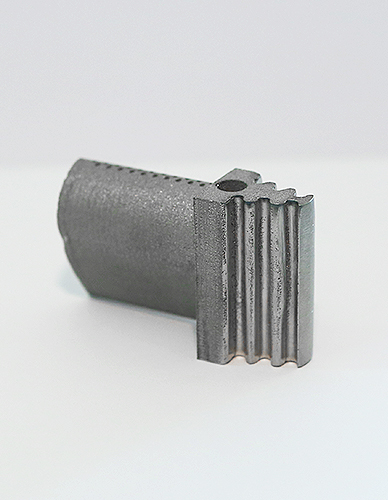

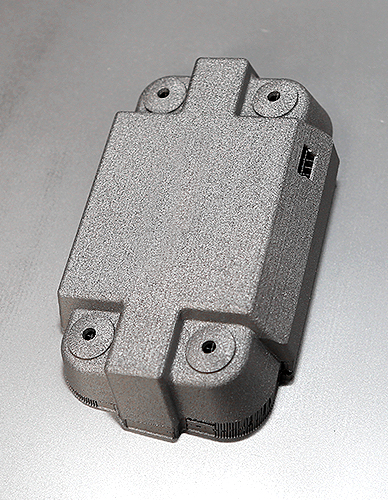

Produce Complex Multi-Process Parts in Single Operation.

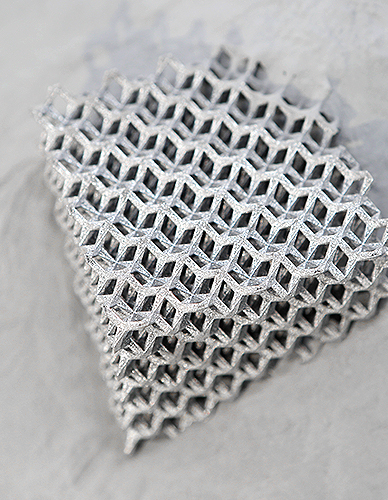

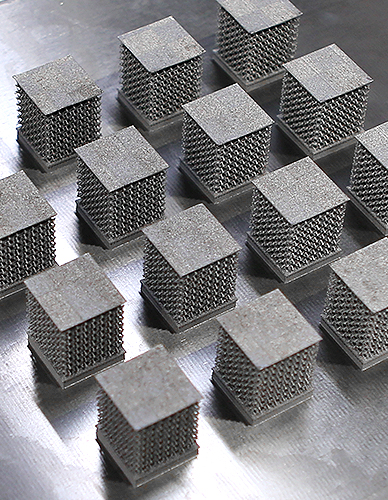

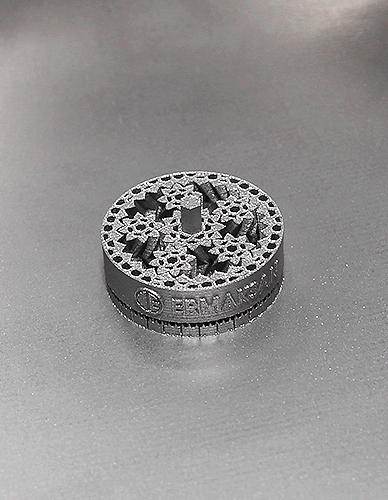

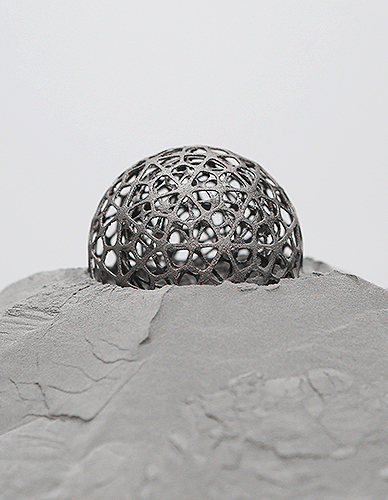

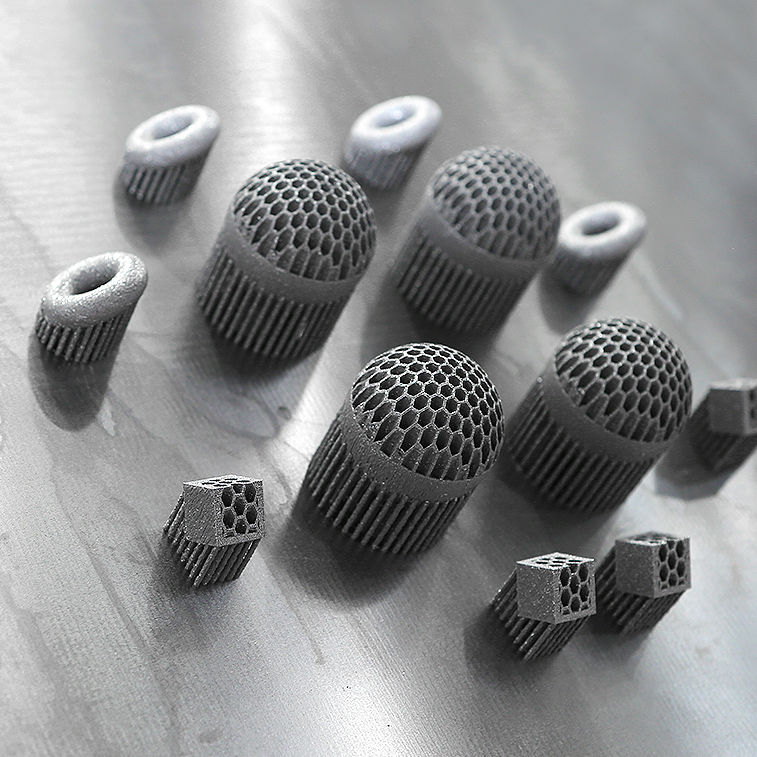

Ermaksan Additive offers ENAVISION 250 to overcome complex difficulties in the industrial field and to make easy production of complex geometries. With its open-access architecture, it allows the use of different types of powder in various sectors.

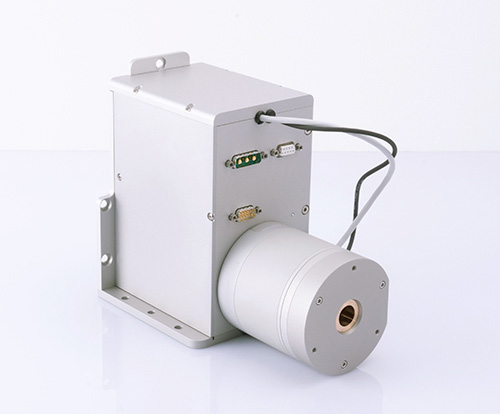

ENAVISION 250; It has a production volume of 250 mm x 250 mm x 300 mm. Offering flexibility and unlimited freedom to users with its open parameter structure, this model is equipped with a single and dual laser versions to meet different customer demands.

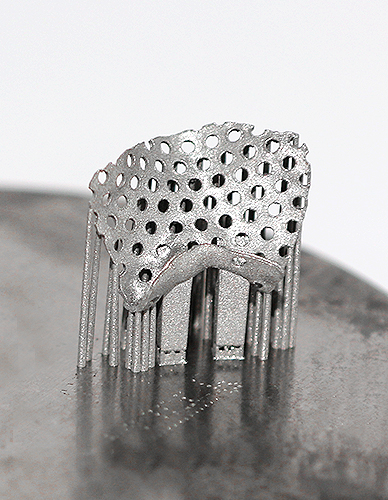

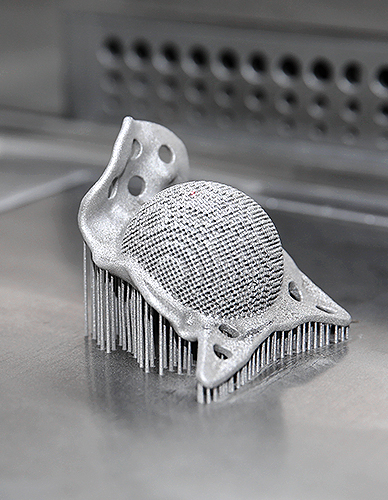

ENAVISION series additive manufacturing products are additive manufacturing technologies using the powder bed fusion (DMLS / SLM) Selective Laser Melting method. In this technology, ENAVISION starts by deposing the metal powder at the desired layer height on the build plate properly and then completely melts the metal powder in the required areas in the part model to be produced by a high power laser. The processes in one layer are performed repeatedly in each layer until the production is completed.

Parts manufactured by laser melting, can be produced with a density of over 99% in standard parts and good mechanical properties. The produced parts can be used as final products by performing secondary processes such as heat treatment, sandblasting, drilling, threading and machining.